Environmentally friendly soldering iron Tsui introduction

With the rise of the green environmental protection movement in the world, people’s awareness of environmental protection is growing. With the introduction of lead-free process, the tip of the soldering iron has a short life and is easy to corrode. We have to introduce advanced foreign plating technology and processing technology to improve production. Lead-free (Pb) corrosion-resistant, long-life, integrated with green products, to create their own “Jian Xin” brand.

First, lead-free soldering iron maintenance

Proper use of the tip and frequent maintenance can greatly extend the service life of the tip. Before soldering, the cleaning sponge must be absorbing water and then squeezing excess water, so that the tip can be cleaned well. The cleaning sponge will damage the soldering tip and cause it to not be tinned!

Second, the correct operating procedures

1. Before soldering, remove the old tin from the soldering iron tip and solder.

2. When the welding stops, put the soldering iron on the soldering iron frame.

3. After the welding work, first adjust the temperature of the soldering iron to 250 °C, then clean the soldering tip and add a new layer of solder for protection.

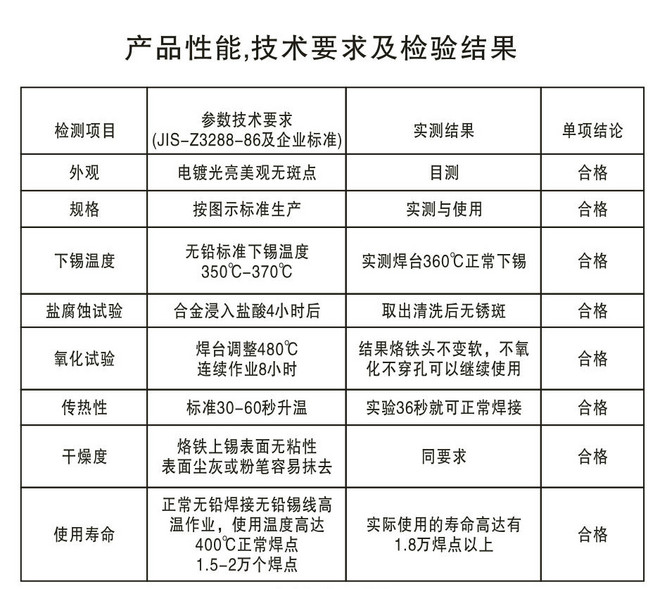

4. Treatment of soldering iron tip oxidation: The above welding process can effectively improve the life of the welding tip by repeatedly using these actions after stopping. Try to use low temperature welding within 380 °C. If the temperature exceeds 450°C, the welding service life will be more than twice shorter than 380 °C.

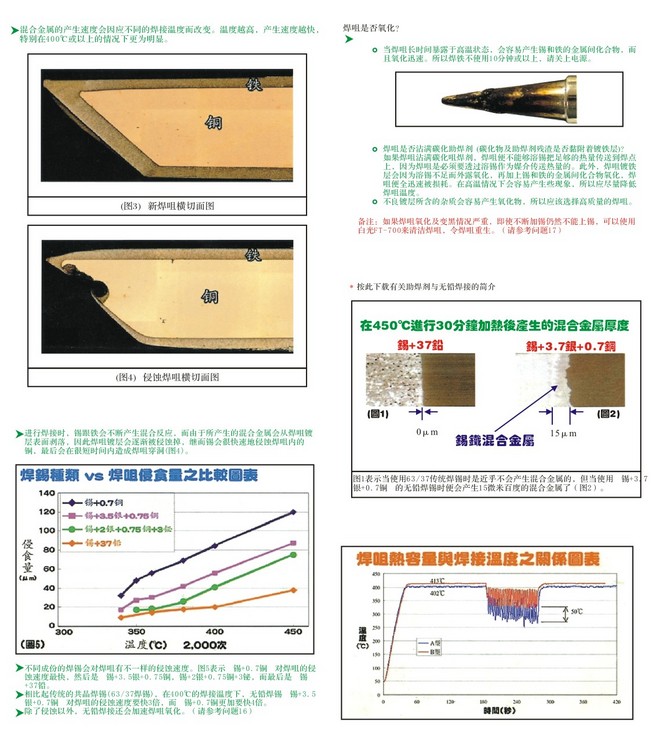

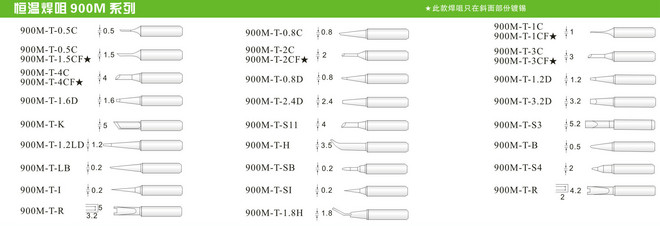

Iron tip analysis chart

Be the first to review “Constant temperature soldering station 900M series”